AI at the Edge: How HVAC Systems Can Predict Their Own Failures

Traditional maintenance approaches for HVAC systems and industrial boilers often relied on reactive strategies—waiting for a failure before taking action. But with the integration of Edge Artificial Intelligence (AI), that era is rapidly coming to an end.

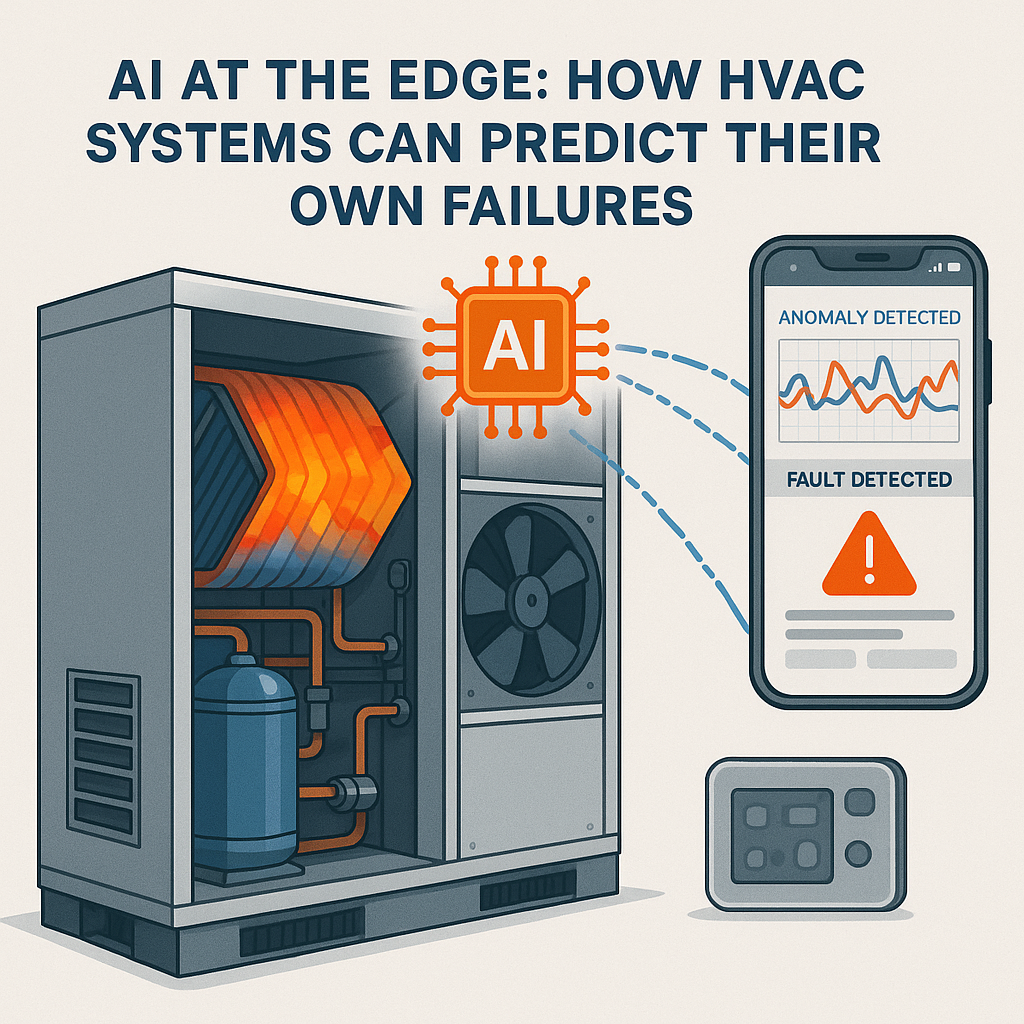

Modern HVAC and boiler systems are now being equipped with embedded AI modules that can monitor performance continuously and intelligently. These systems collect and analyze data in real time—right at the edge, where the equipment operates. By processing sensor inputs like vibration, temperature, and power consumption locally, they eliminate the latency and privacy concerns often associated with cloud-based analytics.

The benefits are transformative. Edge AI can detect subtle anomalies that signal early signs of wear, inefficiency, or potential failure. Instead of waiting for a breakdown, the system can flag issues proactively, enabling timely intervention and predictive maintenance. This approach not only prevents costly downtime but also reduces energy waste and extends the overall lifespan of equipment.

One of the biggest advantages of edge AI is its ability to make decisions instantly, without needing to upload large datasets to the cloud. This ensures faster diagnostics, improved system security, and less dependency on external infrastructure. In environments where real-time response and data privacy are essential—such as manufacturing plants, hospitals, and large commercial buildings—these capabilities are game-changing.

Moreover, as machine learning algorithms continue to evolve, these systems will get even better at understanding operational patterns, learning from past anomalies, and optimizing performance autonomously.

In summary, edge AI is not just an upgrade—it’s a fundamental shift in how industrial systems are maintained and optimized. By combining smart sensors, local processing, and intelligent algorithms, facilities can now operate more efficiently, safely, and sustainably, with minimal manual oversight.